Add to Cart

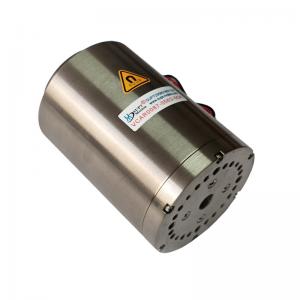

Linear Electric Motors Voice Coil Motor Magnets Light Weight High-Precision

The VCAR series of Cylindrical Actuators constitute nearly 80% of the market ,they can productce a high force with a high acceleration rates.Peak Forces range for 0.7N to 3000N.Typically ,their stroke length is less than 50mm The VCAR Series Actuators Applications include valve Actuators,Z Axis pick and place,small accurate positive displacement metering pumps and both vibrators and active vibration dampening systems. Markets include Medical semiconductor,Aerospace and Automotive.

The use of magnets in VCMs eliminates the need for heavy mechanical structures, resulting in a lightweight design. This feature is especially beneficial in applications where weight reduction is critical, such as aerospace, robotics, and automotive industries. The lightweight nature allows for improved efficiency, reduced power consumption, and enhanced maneuverability.

Furthermore, VCMs provide high precision and accuracy due to their linear motion capabilities. They offer smooth and precise positioning, making them ideal for applications that require fine control and high repeatability. This precision is crucial in areas like medical devices, laboratory equipment, and manufacturing processes where precise movements are essential for optimal results.

The magnets used in VCMs play a significant role in achieving these characteristics. High-performance magnets, such as neodymium or samarium cobalt magnets, provide strong magnetic fields while maintaining a compact size. This contributes to the miniaturization of VCMs, making them suitable for space-constrained applications.

The combination of light weight, high precision, and magnet-based technology makes Linear Electric Motors Voice Coil Motors highly versatile. They find applications in diverse fields, including robotics, automation, positioning systems, optical devices, and more. Their usage extends to areas such as 3D printing, camera autofocus mechanisms, and virtual reality systems.

| Product Model | Peak Force (N) | Continuous Force at 25℃(N) | Total Stroke (mm) | Max Voltage (V) | Back EMF Constant (V/m/s) | Weight of the coil (g) | Stator Diameter (mm) | The Length (mm) |

| VCAR0001-0064-00A | 0.88 | 0.28 | 6.4 | 6.9 | 0.29 | 3 | 9.5 | 17.7 |

| VCAR0001-0010-00A | 0.73 | 0.42 | 1 | 4.8 | 0.6 | 2.7 | 24 | 11.2 |

| VCAR00025-0127-00A | 2.55 | 0.81 | 12.7 | 11.6 | 0.77 | .6.6 | 12.7 | 24 |

| VCAR0006-0039-00A | 6.2 | 1.9 | 3.9 | 6.6 | 1.12 | 7.9 | 20 | 17.2 |

| VCAR0006-0050-00A | 6.2 | 2.6 | 5 | 15.7 | 3.57 | 8.2 | 25 | 18.2 |

| VCAR0007-0040-00A | 7.2 | 2.4 | 4 | 7.5 | 1.88 | 7 | 14.2 | 23 |

| VCAR0007-0064-00A | 7.8 | 2.5 | 6.4 | 9.9 | 1.5 | 7.2 | 19.1 | 23.8 |

| VCAR0007-0127-00A | 7.1 | 2.3 | 12.7 | 12.8 | 1.6 | 11.4 | 19.1 | 27 |

| VCAR0011-0050-00A | 11.4 | 2.1 | 5 | 11.8 | 3 | 11.2 | 24 | 17.2 |

| VCAR0011-0100-00A | 10.5 | 2.9 | 10 | 43.8 | 3.5 | 20 | 31 | 26.8 |

| VCAR0013-0030-00A | 13 | 3.5 | 3 | 16 | 3.5 | 12 | 25 | 21 |

| VCAR0013-0072-00A | 13 | 4.2 | 7.2 | 26.6 | 5.72 | 16.2 | 26.2 | 24.7 |

| VCAR0014-0250-00A | 14 | 4.5 | 25 | 26.5 | 3.9 | 35 | 25.4 | 44.2 |

| VCAR0015-0062-00A | 15 | 6.5 | 6.2 | 26.2 | 9.75 | 14.8 | 33 | 25.6 |

| VCAR0022-0098-00A | 22 | 6.6 | 9.8 | 24.7 | 5.8 | 20 | 34.1 | 35 |

| VCAR0022-0448-00A | 22 | 11.4 | 44.8 | 14.3 | 4 | 52 | 48 | 75.7 |

| VCAR0025-0630-00A | 25.3 | 8 | 63 | 50.6 | 5 | 68 | 31.8 | 83.1 |

| VCAR0030-0150-00A | 29.4 | 4.73 | 15 | 40.5 | 7.4 | 27 | 30 | 31 |

| VCAR0032-0050-00A | 32 | 8.9 | 5 | 29.3 | 7.1 | 48 | 40 | 41.7 |

| VCAR0033-0099-00A | 33 | 8 | 9.9 | 24.3 | 5.87 | 23.5 | 36 | 26.7 |

| VCAR0033-0224-00A | 33 | 13.5 | 22.4 | 26.7 | 6.8 | 69 | 58 | 72 |

| VCAR0035-0090-00A | 35 | 11 | 9 | 26.4 | 9 | 33 | 25.4 | 44.3 |

| VCAR0035-0105-00A | 35 | 15.6 | 10.5 | 11.9 | 5 | 91 | 50 | 67 |

| VCAR0044-0040-00A | 44 | 16.3 | 4 | 18.3 | 8.9 | 46.5 | 53 | 21.2 |

| VCAR0044-0059-00A | 44.1 | 17.7 | 5.9 | 14.3 | 8 | 43 | 46 | 22 |

| VCAR0044-0075-00A | 44 | 13.7 | 7.5 | 16.8 | 7.6 | 38.6 | 31.1 | 35.9 |

| VCAR0044-0249-00A | 44 | 11.7 | 24.9 | 44.9 | 8.88 | 65.9 | 38.1 | 51.3 |

| VCAR0070-0149-00A | 70 | 27.3 | 14.9 | 26.9 | 17.7 | 79 | 43 | 53.7 |

| VCAR0075-0200-00A | 75 | 30 | 20 | 26.2 | 15.2 | 65 | 70 | 38.7 |

| VCAR0080-0129-00A | 80 | 35 | 12.9 | 27.7 | 18 | 149 | 49 | 53.8 |

| VCAR0087-0062-00A | 87 | 21.67 | 6.2 | 34.5 | 12.7 | 45.2 | 43.1 | 34.9 |

| VCAR0087-0563-00A | 87 | 17.5 | 56.3 | 63.4 | 8.1 | 177 | 72 | 110 |

| VCAR0105-0164-00A | 105 | 35.4 | 16.1 | 20.1 | 11.5 | 150 | 60.4 | 40.4 |

| VCAR0110-0380-00A | 110 | 37.4 | 38 | 23.2 | 9 | 150 | 60.4 | 60.4 |

| VCAR0113-0089-00A | 113 | 35 | 8.9 | 31 | 17.5 | 125 | 73 | 27.5 |

| VCAR0115-0065-00A | 115 | 30.1 | 6.5 | 35 | 17.3 | 52 | 40 | 58 |

| VCAR0130-0310-00A | 130 | 40 | 31 | 30.4 | 20.5 | 280 | 75.6 | 56.5 |

| VCAR0140-0150-00A | 140 | 42.2 | 15 | 33.4 | 26.6 | 80 | 53 | 53.7 |

| VCAR0210-0254-00A | 210 | 66.2 | 25.4 | 56.6 | 28 | 230 | 43.7 | 111.8 |

| VCAR0262-0112-00A | 262 | 111 | 11.2 | 35.1 | 41 | 285 | 71 | 64 |

| VCAR0262-0249-00A | 262 | 112 | 24.9 | 28.2 | 26 | 785 | 66 | 109.1 |

| VCAR0294-0498-00A | 294 | 56.8 | 49.8 | 114 | 24.5 | 685 | 93 | 136.9 |

| VCAR0436-0187-00A | 436 | 147.6 | 18.7 | 40.7 | 40.7 | 648 | 80.4 | 91 |

| VCAR0436-0250-00A | 436 | 167 | 25 | 31.6 | 37.2 | 775 | 78.4 | 110 |

| VCAR0436-0373-00A | 436 | 142.6 | 37.3 | 38 | 29.8 | 1050 | 76 | 163 |

| VCAR0980-0249-00A | 980 | 605 | 24.9 | 41.5 | 104 | 1426 | 126 | 134.5 |

| VCAR1351-0310-00A | 1351 | 376.8 | 31 | 73.5 | 68 | 1071 | 110 | 143.7 |

The main application of a voice coil motor:

1.Semiconductor industry:Wiring, cutting, drilling, transportation systems,robotics.

2.Valve operation in the field:Type metering valves, pressure test systems, pneumatic valve chemistry injection system.

3.Micro Machine industry:Feed systems, micro drilling, precision stamping.

4.Vibration System:vibration platform.

5.Medical field:Micro-injection system, respiratory equipment.

6.Aviation Technology:Flight control system, pilot feedback system.

7.Commercial use field:Computer cooling pump miniature camera auto focus system.

8.Automation industry:Laser equipment,dispenser, test equipment, textile machinery.

We are happy to assist a custom design

linear electric motors:

1.Travel: effective travel, used to calculate the the total travel of value force.

2.The direction of movement: horizontal or vertical installation 90 degree.

3.Load force: constant in the reverse direction of force on the motor, such as springs, etc.

4.Load weight: the total quality part of movement, including the quality slider

5.Movement Type: 1.point to point movement; 2.the reciprocation of the rule (e.g. scanning).

6.Velocity curve: 1.a trapezoidal speed curve; 2.triangular speed curve; 3.sine speed curve.

Certifications

We want you to be happy!